Precision O-rings are used as static radial or axial seals in all sectors of mechanical, plant, automotive and equipment engineering.

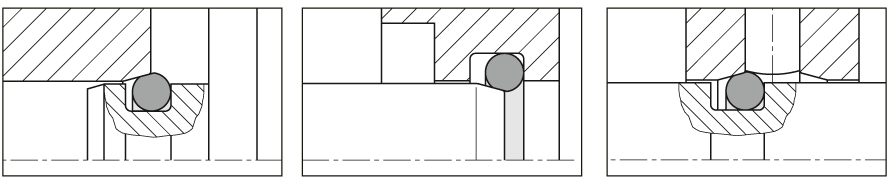

The sealing action of the O-ring is achieved by elastic deformation of its cross-section in a suitably designed housing. The pressure of the fluid being sealed also squeezes the O-ring. The elastomer transfers the pressure evenly in all the effective directions.

Compounds and coatings

ManoyDetect® – Metal detectable materials

In food processing and packaging industry applications ManoyDetect® enhanced materials will allow detector equipment to identify foreign matter in the processed material resulting from a damaged seal. Depending on the sensitivity of the metal detector fitted this offers a high degree of safety and will prevent contamination of the processed material.

ManoyCoat® – Anti-friction coating

ManoyCoat® coated O-rings offer special assembly and disassembly advantages due to their anti-friction properties. For automated assembly, the coating provides smooth feeding. Some of the coatings are also suitable for dynamic applications. FIND OUT MORE >

ManoyPerfluor® – For aggressive chemicals

The ManoyPerfluor® O-ring combines the typical properties of elastomers with the almost universal resistance of PTFE. ManoyPerfluor® compounds are suitable for use with aggressive chemicals and vapours and at temperatures up to +320 °C. Also ideal for aseptic applications.